A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technology to improve image qualities such as addressability and contrast.

TFT LCD is an active matrix LCD, in contrast to passive-matrix LCDs or simple, direct-driven (with segments directly connected to electronics outside the LCD) LCDs with a few segments.

It has the advantages of small size, lightweight, low power, full color, etc.

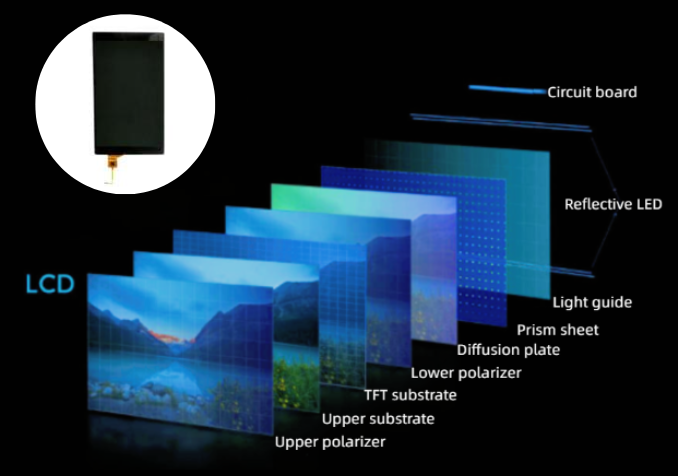

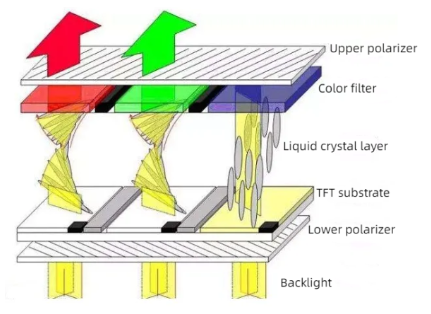

Structure of TFT LCD

TFT LCD is a type of flat panel display that uses thin-film transistor technology to control the alignment of liquid crystal molecules to produce images.

The structure of TFT LCD can be divided into several layers.

- Upper polarize

- Glass substrate

- Color filter (CF)

- Liquid crystal layer (LCD)

- Thin-film transistor (TFT) substrate layer

- Lower polarizer

- Backlight

The structure of TFT LCD is complex, and each layer plays an important role in producing high-quality images.

The backlight provides the light source, while the polarizers help to control the polarization of the light.

The color filter and liquid crystal layer work together to produce color images, and the TFT layer controls the voltage applied to each pixel.

Classification of TFT LCD

According to the material technology of TFT, it can be divided into the following five categories:

- Amorphous Silicon (a-Si) TFT LCD

a-Si TFT LCD is the first commercialized TFT technology.

Due to the advantages of a simple manufacturing process, good stability, and low cost.

They are widely used in electronic displays, such as computer monitors, TVs, mobile phones, PDAs, etc.

- Low-Temperature Polysilicon (LTPS) TFT LCD

LTPS TFT LCD is a new type of thin-film transistor technology.

It is manufactured using low-temperature polysilicon technology and has the advantages of high resolution, high response speed, and low power consumption.

They are widely used in high-end mobile devices like smartphones, tablets, etc.

- Indium Gallium Zinc Oxide (IGZO) TFT LCD

IGZO TFT LCD is a new type of thin-film transistor technology.

It is manufactured using oxide semiconductor materials and has the advantages of high transparency, low power consumption, high response speed, etc.

They are widely used in laptop displays, flat-panel TVs, etc.

- Oxide TFT LCD

Oxide TFT LCD is a new type of thin-film transistor technology.

It is manufactured using oxide semiconductor materials and has the advantages of high transparency, high resolution, high response speed, etc.

They are widely used in display screens and electronic paper.

- Microcrystalline TFT LCD

Microcrystalline TFT LCD is a new type of thin-film transistor technology.

It is manufactured using microcrystalline silicon materials and has the advantages of high resolution, high brightness, low power consumption, etc. It is widely used in flat-panel TVs, projectors, etc.

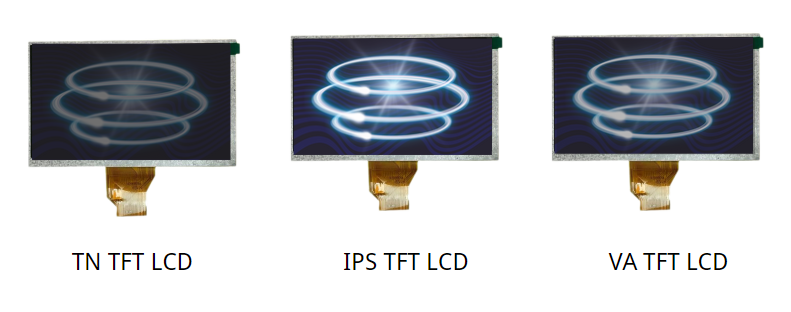

Type of TFT LCD

According to the physical structure, TFT LCD can be divided into the following three types

- Twisted Nematic (TN) TFT LCD

TN TFT LCDs are the most common type of LCDs.

They consist of a layer of liquid crystal material sandwiched between two polarizing filters.

The liquid crystal material is twisted at a certain angle between the two polarizers, and the orientation of the liquid crystal molecules can be controlled by applying an electric field to the material.

This causes the polarization of light passing through the display to be rotated, allowing the display of images.

- In-Plane Switching (IPS) TFT LCD

IPS TFT LCDs use a different structure than TN LCDs.

They have two glass substrates with transparent electrodes and a layer of liquid crystal material between them.

The liquid crystal molecules in IPS TFT LCD are aligned parallel to the substrate, and the orientation of the molecules can be controlled by applying an electric field.

IPS TFT LCDs have wider viewing angles and better color reproduction than TN LCDs.

- Vertical Alignment (VA) TFT LCD

VA TFT LCDs also uses a layer of liquid crystal material between two glass substrates with transparent electrodes.

In VA TFT LCD, the liquid crystal molecules are oriented perpendicular to the substrate when no electric field is applied.

When an electric field is applied, the molecules rotate and align themselves parallel to the substrate.

VA TFT LCDs have higher contrast ratios than TN and IPS TFT LCDs.

Related: TN vs. IPS vs. VA: What’s the Best LCD Display Technology?

Common interface types of TFT LCD

TFT LCDs typically use one of several interface types to communicate with the host system. The most common interface types are:

- LVDS (Low-Voltage Differential Signaling)

- MIPI (Mobile Industry Processor Interface)

- RGB (Red, Green, Blue)

- DVI (Digital Visual Interface)

- HDMI (High-Definition Multimedia Interface)

- SPI (Serial Peripheral Interface)

The choice of interface type depends on factors such as the required data transfer rate, the host system’s complexity, and the interface’s power consumption.

Each interface type has its own advantages and disadvantages, and the appropriate interface type should be selected based on the specific application requirements.

Conclusion

At this stage, with the development of the display panel technology and product iterations, the LCD industry has matured and become the mainstream of the market.

Nowadays, TFT LCD can be found everywhere, from industrial control panels to ATMs, medical devices, and consumer electronics.

They have revolutionized how we interact with technology and become an essential part of our everyday lives.

Therefore, when choosing an LCD monitor, the most suitable technology should be selected according to the specific application requirements and budget.

If you want to know more about the TFT LCDs, feel free to contact our engineer term.