Hongguang Display

China Display Manufacturer,Global Supplier

Menu

China Display Manufacturer,Global Supplier

Menu

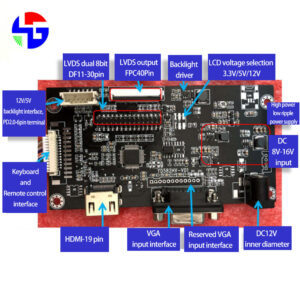

Model: HGYD2690H-V1

Size: 78.00mm×50.00 mm×13.50 (mm)(L×W×H)

Signal Input: VGA | HDM

Signal Output: LVDS

Supply Voltage: 3.3 | 5 (V)

Resources: Specifications

The HGYD2690H-V1 LCD driver board is mainly designed for TFT LCD screens and is suitable for LCD screens and some other flat panel displays.

|

Outline Dimension |

78.00mm×50.00 mm×13.50mm(L×W×H) |

|

Display Interface |

LVDS/TTL |

|

Display Color |

24-bit (3×8, 16.7M) |

|

Operation Interface |

OSD operation interface with visualization |

|

Communication Interface |

Digital keys, Infrared (IR), I²C |

|

Control Area |

LCD resolution ranging from 800×480 to 1920×1200 |

|

Operating Temperature |

-20℃~80℃; -30℃~80℃ (except main chip) |

|

Storage Temperature |

-40℃ to 70℃ |

|

Working Environment |

Atmospheric Pressure Range: 70kPa to 106kPa |

|

MTBF |

>100,000 hours |

|

Display Voltage |

Jumper selectable between 3.3V and 5V |

|

Signal Input |

VGA, HDMI |

To ensure the quality of our products, we have implemented a series of quality control measures.

| Production process control |

We strictly control every aspect of our production process, including material selection, production technology, and equipment maintenance. Our production process has been optimized to ensure that our LCD displays meet the required quality standards. |

| Automated testing equipment |

We have introduced advanced automated testing equipment to comprehensively and quickly test all aspects of our LCD displays. Automated testing equipment increases testing efficiency and accuracy, providing essential support to our quality assurance efforts. |

| Manual testing |

Although automated testing equipment can comprehensively test all aspects of LCD displays, manual testing is still an essential part of our quality assurance process. Our professional-quality management team conducts manual testing on every LCD display to ensure that our products meet the required quality standards. |

| Sampling inspection |

We implement sampling inspection throughout the production process to ensure that each batch of LCD displays meets the required quality standards. Our quality management team conducts sampling inspections at each stage of production. |

| Quality management system | We have established a comprehensive quality management system, including the development of strict quality standards, the establishment of a sound quality management process, and the training of professional quality management personnel. |

| Supervision and inspection | We regularly invite third-party inspection agencies to conduct supervision and inspection of our production process and products to ensure that we comply with quality management systems and standards. |

| After-sales service | We provide comprehensive after-sales service, including product quality guarantee periods, product maintenance, returns, and exchanges. Our after-sales service ensures that consumer rights are protected, increasing customer satisfaction and loyalty. |

Yes, you can order samples directly.

Samples in stock will be shipped within 2 days, It takes 1-2 weeks for sample transformation and 3-5 weeks for mass production; Customized products within 2-3 days of developing plan, and 1 week in drawing approval sample production; Test run/batch production 4-5 weeks after sample approval.

Samples are usually shipped by air (UPS, Fedex, DHL, EMS), which generally takes 3-7 working days, and bulk products can be shipped by air or sea, which usually takes 3-5 weeks

Let us know your requirements or applications first, we will offer you a reasonable price according to your requirements.

Sample orders need to pay 100% payment, bulk orders can pay 50% deposit to start material preparation.

Yes, please formally inform us at the design stage and we will make samples with your logo for your sample testing and approval.

Yes, we provide free technical support for pre-sale samples; regularly follow up on the use of products during sales; after the sale, our company provides a 1-year warranty (except for human reasons).

If you’re looking to prototype and test with our display, we offer an example code library to help you get started. This library includes sample code that you can use as a starting point for your own projects.

If you need, we will provide IC Datasheets to you to help you complete the development process. With these resources at your fingertips, you can quickly and easily prototype and test your display designs.

Each of our products has a link to download the specification. You can find the product and browse by our TFT LCD display, OLED display, custom display, and LCD controller board, and click the product name to access the product specification details.

We provide the highest quality and most professional technical support services. If you have any issues or need assistance with our LCD screens, our technical support team is always ready to help and support you.

In addition to providing design and manufacturing services for LCD screens, we also provide comprehensive program support services to help customers realize their unique display requirements. Our scheme support services include comprehensive support from preliminary concept to complete design

We provide a variety of customization options according to customer needs, such as screen size, resolution, brightness, contrast, touch technology, appearance design, etc. Our team can also provide technical guidance and design advice to help customers choose the best LCD solution.

Model: HGYD582HV-V01

Size: 107mm×56.4 mm×16.5 (mm)(L×W×H)

Signal Input: VGA | HDM | RGB

Signal Output: LVDS

Supply Voltage: 3.3 | 5 | 12 (V)

Model: HGYD2680HV-V9

Size: 114.00 x 70.00 x 16.50 (mm) (W x H x D)

Signal Input: VGA | HDM | RGB

Signal Output: LVDS dual 8-bit | TTL 18-bit/24-bit

Supply Voltage: 3.3 | 5 | 12 (V)

Resources: Specifications

Model: HGYD2686DHV-V1

Size: 107.00 x 65.00 x 16.50 (mm) (W x H x D)

Signal Input: VGA | HDM | Analog RGB | PAL | NTSC

Signal Output: EDP 2lane or 4lane | LVDS dual 8-bit

Supply Voltage: 3.3 | 5 | 12 (V)

Resources: Specifications

China Display Manufacturer,Global Supplier

2nd Floor, Building 1, Longquan Information Technology Industrial Park, Henglang Community, Dalang Street, Longhua District, Shenzhen, China 518109

Copyright © 2023. Shenzhen Hongguang Display Co. Ltd. All rights reserved.